The areas of application of forming simulation in the Department of Forming and Cutting Processes are divided into two groups at the institute. The first area of application of forming simulation comprises method planning, i.e. the development of multi-stage forming processes and their evaluation with regard to process reliability against component failure, dimensional accuracy after component springback and robustness analyses within given manufacturing and material tolerances. The second field of work is the numerical investigation of material behavior under uniaxial and multiaxial loading, whereby new criteria for describing the forming capacity under defined and non-linear load cases are developed and also validated experimentally.

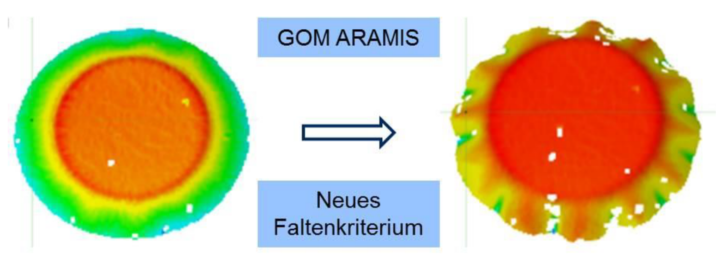

In-situ observation of wrinkle formation of the 2nd kind using the GOM ARAMIS optical measuring system.

In this project, an innovative wrinkle criterion is being developed in cooperation with the automotive industry. The aim of this project is the implementation of this wrinkle criterion in the software packages OpenForm and AutoForm for the simulative prediction of wrinkles of the 2nd kind in the deep drawing process. The use of thinner, high-strength sheet materials poses a challenge for sheet metal forming processes, as thin sheets are more prone to wrinkling in the free forming zone during the forming process, especially during deep drawing (wrinkling of the 2nd kind), than sheets with higher sheet thicknesses. These folds impair the component function, subsequent joining operations during assembly or are visually unacceptable. In addition, the resulting wrinkles can usually not be removed by further process steps.

The results to date show that pre-strains with non-linear strain paths have a major influence on the wrinkle boundaries. The procedure for detecting and evaluating the onset of wrinkles has been further developed so that it can already be used in method planning during the design phase of the drawing die. Further work is currently focusing on the verification of the determined wrinkle limits using modular tools, which represent sections of real geometries with the risk of wrinkle formation.

Duration: 04.2016 - 11.2018